XIAMEN UN MAGNET CO.,LTD. (UNMAG) is a high-tech enterprise in manufacturer and distribution of permanent magnet and magnetic related components.Including Neodymium magnet, Alnico magnet, SmCo magnet, Ferrite magnet and various of magnetic products.With an in-house R&D laboratory, We are able to manage and support contracted magnet projects from both the government and private sector.

All the products are approved by TS16949 & RoHS, moreover, they are enjoyed lifetime technical support.

We have 21,500 square meters, 180 staffs(Production: 108; Quality: 10; R&D: 15; Others: 47),3 sets of 600 kgs strip casting furnace,15sets sintering furnace,175 sets wire cuttiing machine, 77 sets of grinding machine and 3 electroplating production lines.They can produce 100 tons of NdFeB magnet per month and 20 tons of SmCo magnet per month.

Our comprehensive customer services have secured buyers worldwide. We have a team dedicated to answering any inquiry regarding our product features and technology. They can even provide you with technical support for magnet installation.

We provide OEM and customization service to meet your market requirements. We will continue our aggressive drive to expand the international market. Warmly welcome any overseas partners to cooperate with us now.

◼ Product Advantage

From the magnetic properties, mechanical properties, physical and chemical properties of rare earth permanent magnets, to the surface coating characteristics of magnets, and the magnetization characteristics of related components, we are able to provide customers with the best cost-effective solution.

We self-designed grinding equipement.The tolerance of final products can be within 0.03mm,The thickness of the thinnest block magnet we can produce is 0.5mm.Max length of block magnet could be 240mm,The thickness of the thickest block magnet we can produce is 60mm.

◼ Development Ability

---Engineering design

Possess CAXA, ProE, Solidwork 2D & 3D design and development capabilities.

---Electromagnetic simulation

Equipped with Ansys electromagnetic field simulation capabilities, it can quickly and economically analyze the influence of electromagnetic fields on the system.

---Fixture development

With the ability of automatic programming control, the development, manufacture and application of special equipment and tooling can greatly improve the efficiency.

---Performance formula

With magnetic material powder metallurgy molding process, the material has a unique performance formula, which 100% meets customer customization requirements.

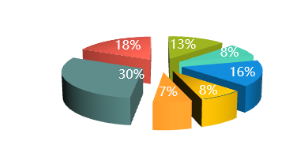

◼ Application Areas

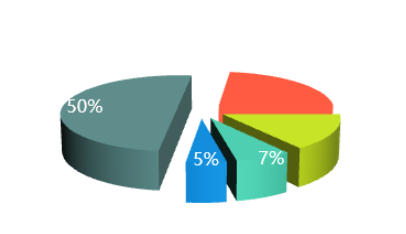

◼ Main Market

12 years magnet customization serivce R & D and production expert,Serve for World-Class enterpries include: Continental,a chain supplier of automative parts for Audi,Benz.Hayward Tyler,a global l

UNMAG have 21,500 square meters, 180 staffs(Production: 108; Quality: 10; R&D: 15; Others: 47),3 sets of 600 kg strip casting furnace,15sets sintering furnace,175sets wire cuttiing machine,77set

From pre-sale to after-sale,UNMAG sales team to provide clients with quality service.Focus on the customer's application,Our professional engineers could help to get final magnets from product des

1.UNMAG advanced production technology determines the performance and quality of magnets.(Include Strip Casting technology,Hydrogen Decrepitation technology,Jet Milling tenology etc.)Technology advant

online service

online service +86-592-5130661

+86-592-5130661 [email protected]

[email protected] +86-18359200916

+86-18359200916 +8618359200916

+8618359200916